Manufacturing Planning and Execution

Click on the image to see relevant details

The overall manufacturing planning process is comprised of:

- The forecast values and requirements from the sales information system and

costing/profitability analysis are inputs to the Sales and Operations Planning

(SOP) phase in which independent requirements are determined.

- Master Schedule items (those items that greatly influence profits or

consume critical resources ) are planned. Planning the master schedule items

separately leads to a reduction in stock levels and improved delivery

performance.

- Materials requirements planning (MRP) is the final step in the planning

process. The output of MRP is either a planned production order, a purchase

requisition, or a planned purchase order.

The overall manufacturing execution process is comprised of:

- Production orders are released

- Materials are issued

- Completion confirmations are performed

- Goods are received into stock.

The manufacturing process affects capacity, costing inventory, reporting,

and analysis.

The five primary phases are:

- Sales and operations planning

- Demand management

- Master production planning

- Materials requirements planning

- Production order execution

The forecast values and/or requirements from customer order management,

sales information system, and controlling are inputs to the sales and operations

planning phase.

The main steps in sales and operations planning are:

- Creating a sales and production plan--Methods

- Manual entry

- Forecast of consumption

- Copying data from financial modules

- Copying data from the sales information system

- transferring product group

- Disaggregating the planning values

- Transferring the planning values to demand management

There are four ways to create a production plan in the system.

- Based on sales

- Based on target inventory

- Based on current days of sales supply

- Based on running down the inventory to zero (Just in Time or Kanban)

Demand management links top-level requirements planning (SOP) with materials

planning (MPS and MRP)

- Demand Management determines the requirements dates and quatities for

important assemblies and specifies the strategies for planning and producing or

procuring finished products.

- The result of Demand Management is the demand program

- The demand program distinguishes planned independent requirements and

customer independent requirements

- The requirements can then be transferred to MPS or directly to MRP

depending on the MRP type selected in the material master of the material.

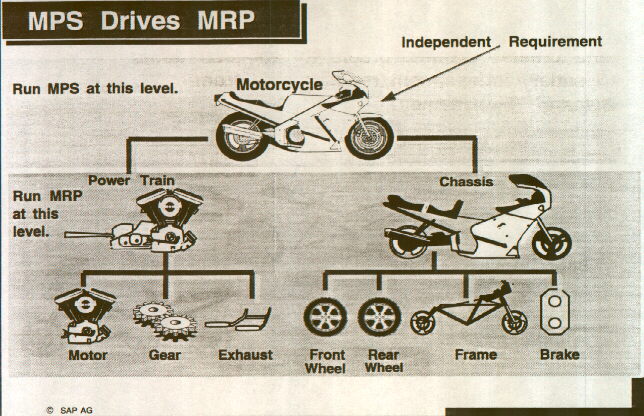

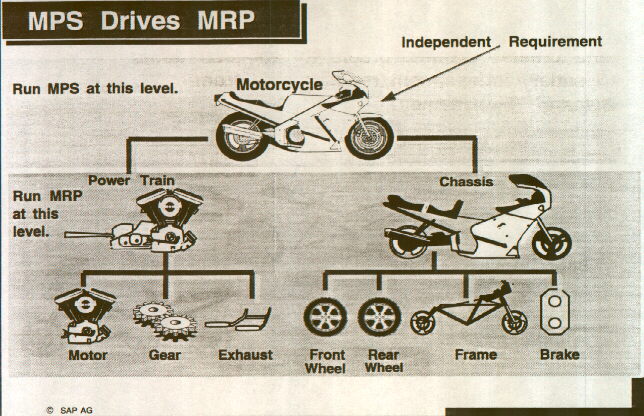

The independent requirements from Demand Management initiate the master

scheduling process for MPS designated items

The master production schedule is the anticipated build schedule (high

level)

- The purpose of MPS and MRP is to guarantee availablility

- The MPS run results in planned orders for the master schedule items and

dependent requirements for the level directly below the MPS items.

- MPS = Finished goods level only

- In material requirements planning (MRP), the system calculates the net

requirements while considering available warehouse stock and scheduled

receipts from purchasing and production.

- The uses of MRP are as follows:

- MRP is used to plan the on time production or procurement of the required

quantities for both internal consumption and customer demand.

- This process involves monitoring stock levels and automatically creating

order proposals for purchasing and production.

- For materials produced in-house, the dependent requirements of teh

conponenets are determined during BOM explosion.

- BOM explosion is the process by which the system calculates the componenets

or assemblies required to produce the material.

- MRP requires exact requirement quantities, which allows you to work with

particularly low safety stocks.

- The output of MRP is either a planned production order, a purchase

requisition, or a planned purchase order.

- A planned order can be converted to a production order (for materials

produced in-house) or a purchase requisition for procured materials.

Manufacturing Execution is intitated by releasing each production order to

the shop floor.

Production Orders: Contents

- Production orders are used:

- To control and monitor production within a factory

- As a controlling instrument for cost accounting

- The production order displays:

- what and how much is to be produced (including duration)

- when production is to be executed

- what is required for production (components, resources)

- which method of production to be used

- the capacities required e.g. machine, labor

- production costs

Production Order Execution Process

- Production orders go through a series of steps including:

- Production order release

- Goods issue (issuing the components or raw materials)

- Completion confirmation confirming that the final material is complete

- Goods receipt (receiving the finished good back into inventory)

- Order settlement