| 8. Prevention by Design | |

|

8.6 Areas Requiring Consideration at Design Stage |

|

2. Joints and Faying Surfaces

In joining of two surfaces, crevice formation and galvanic effects are two major considerations. The formation of crevice must be avoided by sealing or shielding the crevice from the environment. To minimize galvanic corrosion the two metals must be insulated.

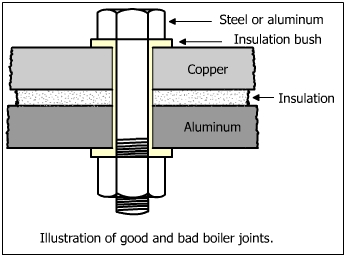

In good design practice all joints should be designed to be permanent and watertight and the direct contact of the two metals must be avoided by means of insulating materials or by applying protective coatings. All components must be effectively insulated. Figure below illustrates a bad design practice related to bolted joints.

Figure 8.17 illustrates how two metals differing in potential, e.g., copper (Eo = 0.334 V) could be joined with Al (Eo = -0.162 V) without the risk of galvanic corrosion by inserting insulation sleeves and washers between copper and aluminum.

Figure below illustrates how two dissimilar plates of aluminum and steel could be joined without the risk of galvanic corrosion by insulation with either jointing compounds, or insulating inserts and insulating washers. The galvanic corrosion can be minimized by proper insulation as shown here. When two dissimilar metals are to be joined, either paint both the metals or only the more noble metal.

|

|