| 8. Prevention by Design | |

|

8.6 Areas Requiring Consideration at Design Stage |

|

1. Bimetallic Contact

(e) Contact With Wet Insulation Materials

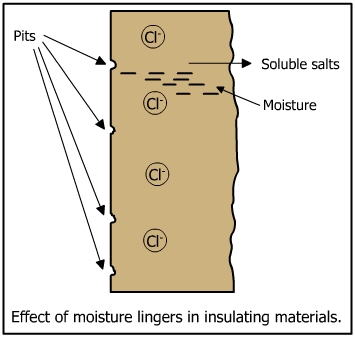

Insulation materials, such as glass wool, glass fibers, polyurethane foam, do not cause the corrosion of steel in contact with insulation as long as the insulation material remains dry. Corrosion underneath the insulation, however, assumes significant proportions if the insulation becomes wet during storage, operation, or field erection. Following are the factors leading to insulation-induced corrosion:

1) Ingress of moisture in the insulation resulting in the leaching of soluble salts of low pH (~2-3).

2) Release of chloride ions.

3) Destruction of passivity of steel by chloride ions and initiation of pits.

4) Weather cycles, such as wet-dry, hot-dry, and damp-warm cycles, which induce high corrosion rates.

5) Inadequate moisture barriers because of inadequate spacing of insulation.

A schematic sketch of moisture ingress is shown in figure below.

Following figures show the corrosion caused by ingression of moisture in insulation in water heater after six months of service.

|

|

|

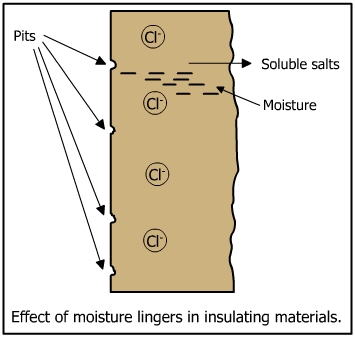

Corrosion induced by insulation can be prevented by the following measures:

1) Eliminating flat horizontal surfaces.

2) Structural design which trap water (example: H-beams and channels)

3) Strict compliance of insulation thickness.

4) Providing an adequate moisture barrier and waterproofing.

5) Addition of sodium silicate as an inhibitor.

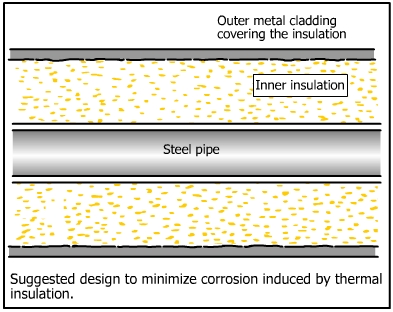

An idealized design to prevent insulation-induced corrosion is shown below.

|

|