|

|

| 8. Prevention by Design | |

|

8.6 Areas Requiring Consideration at Design Stage |

|

1. Bimetallic Contact

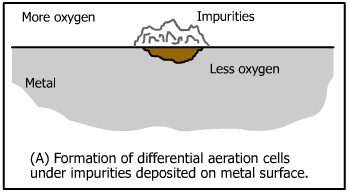

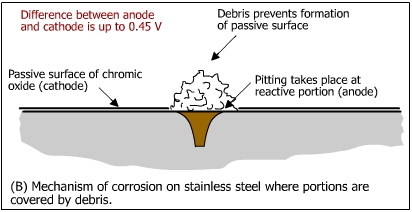

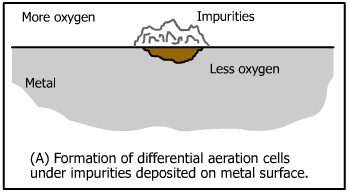

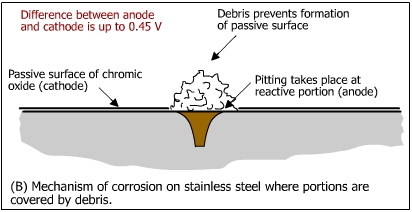

(c) Deposition of Impurities

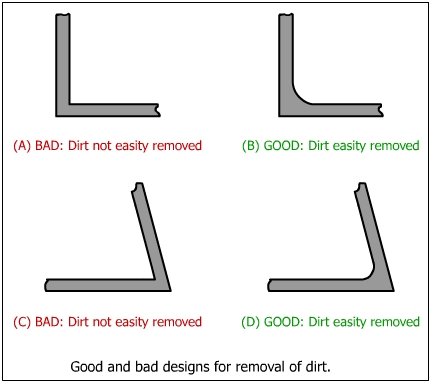

The deposition of impurities must not be allowed. The deposition of impurities cause the formation of differentiate aeration cells and allows the absorption of moisture from the air which leads to corrosion (Figures A and B).

|

|

The debris or deposits formed allow the creation of differential aeration cells. The passive surface of steel may be destroyed by such deposits. The sites under the deposits become the anodes and lead to pitting. A significant difference between the anodes and cathodes may be observed. Hence, a good design should not allow the built-up of impurities on the surface.

In Figures (A) and (B) the dirt and impurities cannot be easily removed, hence, the two designs are poor designs. Impurities or deposits can easily be removed in designs shown by Figures (C) and (D).

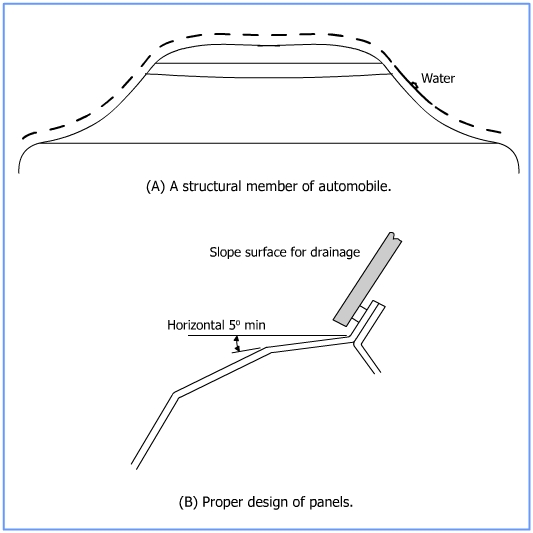

Figure below shows good and poor designs against rain.

In automobiles, structural members must be designed to minimize the retention of water on the surface. Some examples of preferred orientation and design are shown in figure below .

|

|