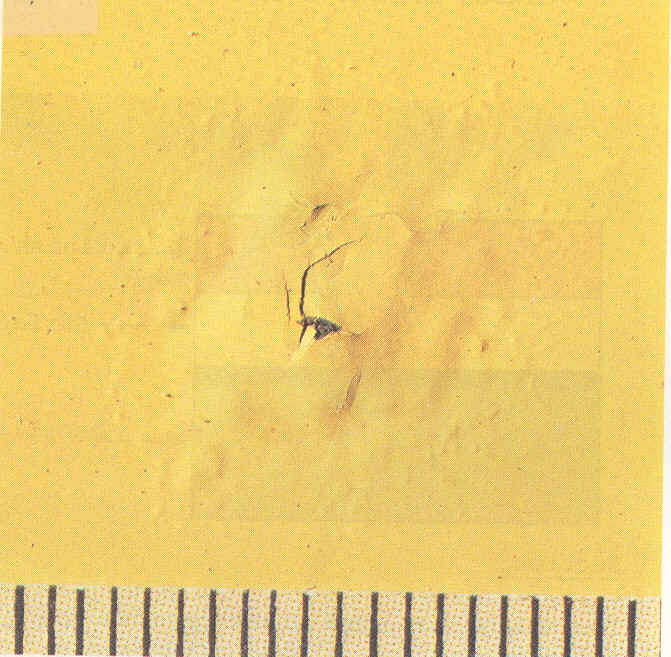

(A) Blistering

Identification:

Formation of large broken or unbroken bubbles or hollow dome shapes on the surface of a painted substrate.

Description:

The following are the major causes leading to blistering:

-

Application of paints over oil contaminated surface. Oils and waxes on the substrate do not allow good adhesion.

-

Solvent retention: Solvents retained due to incomplete release increase absorption of moisture and water causing loss in adhesion and blister formation.

-

Applying an organic top coat over a porous inorganic coat on a warm substrate. Blisters are formed and broken and leave the substrate surface exposed to environment.

-

If excessive cathodic protection is applied, the hydrogen formed under the coating pushes the coating because of increased vapor presence.

-

Soluble salts formed as a result of inadequate rinsing or presence of prior corrosion sites create active sites for the formation of blisters.

-

Application of high performance coating over an incompatible shop primer (a special primer applied on steel after it has been cleaned in a centrifugal machine) may lead to blister formation on the substrate.

Remedy:

-

The damaged areas should be stripped back to the base metal and the coating re-applied on the damaged areas.

-

If the damage is extensive, it may be necessary to remove the entire coating, clean the substrate and re-apply the entire coating.