|

5. Cathodic Protection |

|

|

5.3 Cathodic Protection Systems [3/8] |

|

Important Characteristics of Galvanic anodes

Energy contents (amp/hr/lb or lb/amp/year): The energy content of magnesium anode is 1000 amp/hr/lb which means that if 1 ampere of current is to be discharged continuously, 1 pound of Mg anode would be consumed in 1000 hours. Similarly, if 1 lb of zinc (energy content 372 amp/hr/lb) would be consumed in 372 hours. The other unit is lb/amp/year which is obtained by dividing hours per year by amp/hr/lb.

Solution potential (open circuit potential): Zinc and Mg anodes have their own solution potentials with reference to a standard Cu-CuSO4 reference electrode. The solution potential of Mg anode is nearly -1.55 Volts vs Cu-CuSO4.

Driving potential: It is the difference between the solution potential and the potential of the polarized structure taken to be -0.85. On tis basis, standard Mg alloy has a driving potential of (1.55 - 0.85 = 0.70 V).

An anode bed is comprised of a number of anodes buried in a backfill surrounding the soil. The life of the anode bed is determined by

weight of the anode (inverse of the consumption rate)

utilization factor (0.85)

efficiency

Ground resistance: It would be described under ground bed design.

Installation of Anodes

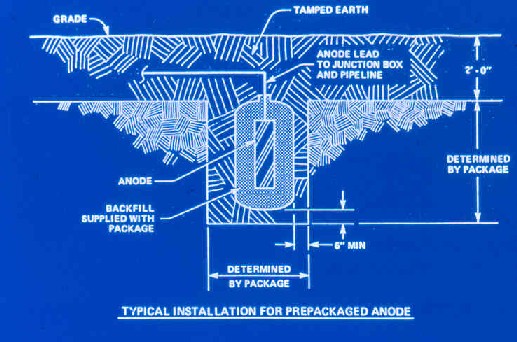

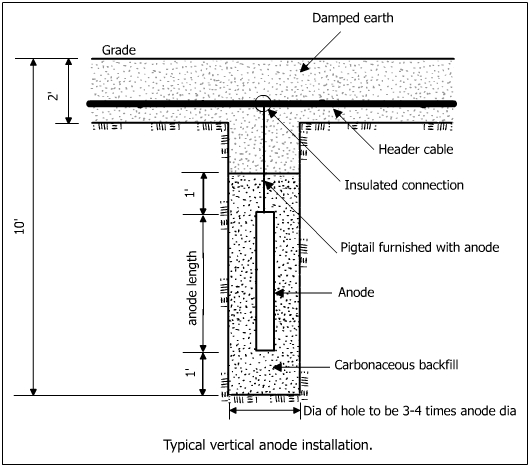

A single packaged installation is shown below.

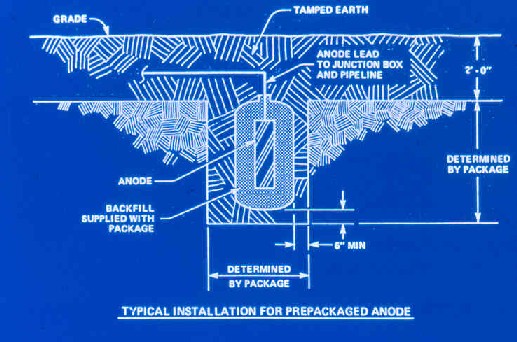

A non packaged installation is shown below.

The anode packed in a backfill is buried in the ground at a pre-determined distance from the structure and at a specified depth. The anode cable is thermite welded with the structure as shown earlier. The anode should contain sufficient material to ensure a service life of about twenty years.

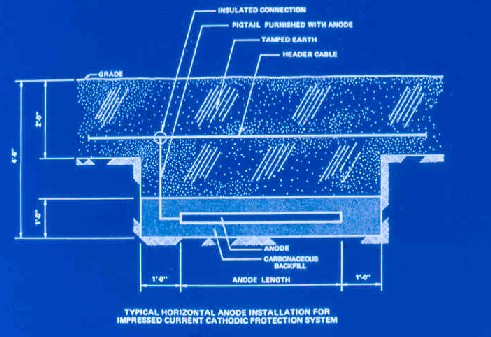

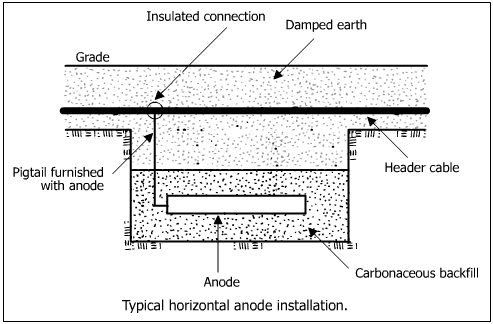

Anodes can be installed as deep-vertical, shallow-vertical, shallow-horizontal and shallow-vertical. Horizontal and vertical installation of galvanic anode is shown below. Vertical anode beds are preferred over horizontal anode bed. However, due to soil depth at the anode bed location or to the proximity of other underground structures, horizontal anode beds are used. The anode should be placed in moist soil system.

Applications

Low resistivity environment

Non-availability of power

Lower current requirement

Temporary requirement

Conjested areas of pipeline crossing

Sub-marine pipelines

Ships and naval vessels

Dockyards

|

|