| 4. Forms of Corrosion | |

|

4.6 Stress Corrosion Cracking [1/4] |

|

Stress Corrosion Cracking (SCC)

Stress corrosion cracking is the formation of brittle cracks in what otherwise appears to be sound material. It is induced by the simultaneous action of tensile stress and corrosive environment. The stress can either be applied in the form of residual stress. Residual stresses can be introduced in cold deformation and forming, welding, heat treatment, machining and grinding. The residual stresses induced during welding may approach the levels of yield strength. Stresses of sufficient magnitude are also introduced by corrosion products.

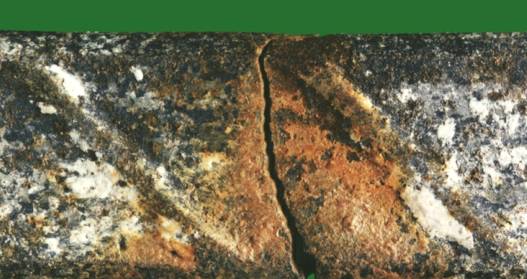

Stress corrosion is insidious and unpredictable. Sudden failures occur without any visible symptoms (see figure below).

Stress corrosion cracking in steel rods in a pre-stressed concrete block.

Recognition and types of SCC

The SCC crack is multibranched. The surface remains bright. Various types of SCC can be distinguished.

|

|

|

|

|

|

|

|

|

|

|

|