ASSIGNMENT NUMBER 3 – SOLUTION KEY

Problem: Do a proportion

a trial mixture that will meet the following conditions and specifications.

Conditions and Specifications: Concrete is required for a pavement that will be exposed to chlorides from seawater. A specified compressive strength, f'c, of 40 MPa is required at 28 days. Slump should be between 25 mm and 75 mm. A nominal maximum size aggregate of 25 mm is required. No statistical data on previous mixes are available. The materials available are as follows:

Cement: Type I with relative density of 3.0.

Coarse aggregate: Well graded, 25-mm nominal maximum-size rounded gravel with ovendry relative density of 2.7, absorption of 0.5% and ovendry rodded bulk density of 1700Kg/m3. The laboratory sample for trial batching has a moisture content of 1.5%.

Fine aggregate: Natural sand with ovendry relative density of 2.60 and absorption of 0.6%. The laboratory sample moisture content is 5%. The fineness modulus is 2.80.

Water reducer: reduces water demand by 10% when used at a dosage rate of 4 g per Kg of cement. Assume that density is that of water.

SOLUTION:

Strength. The minimum design compressive strength for concrete exposed to chlorides from sea water is given as 35 MPa. (Table 9-1).

Table 9-1. Maximum

Water-Cementitious Material Ratios and Minimum Design Strengths for Various

Exposure Conditions

|

Exposure Condition |

Maximum water-cementitious

material ratio by mass for concrete |

Minimum design compressive

strength, f' c , MPa (psi) |

|

Concrete

protected from exposure

to freezing and thawing, application of deicing chemicals, or

aggressive substances. |

Select

water-cementitious material ratio on basis of strength, workabilty, and

finishing needs |

Select

strength based on structural requirements |

|

Concrete intended to have low

permeability when exposed to water |

0.50 |

28 (4000) |

|

Concrete exposed to freezing and

thawing in a moist condition or deicers |

0.45 |

31 (4500) |

|

For

corrosion protection for reinforced concrete exposed

to chlorides from deicing salts, salt water,

brackish water, seawater, or spray from these sources |

0.40 |

35 (5000) |

Thus, we see here that the required design strength is 40 MPa. Since no statistical data is given , as per table 9-11,

The required compressive strength for proportioning f'cr is given by: 1.10f'c + 5.0

i.e. f'cr = 1.10*40 + 5.0 = 49.0 MPa.

Table 9-11. (Metric).

Required Average Compressive Strength When Data are Not Available to Establish

a Standard deviation

|

Specified compressive strength,

f'c , Mpa |

Required average compressive

strength, f' cr, Mpa |

|

Less than 21 |

f' c + 7.0 |

|

21 to 35 |

f' c + 8.5 |

|

Over 35 |

1.10 f' c + 5.0 |

w/c ratio: According to Table 9-1, the maximum w/c ratio for concrete exposed to chlosrides from sea water is 0.40. However , the recommended w/c ratio on basis of compressive strength as per Fig 9-2 or table 9-3 is :

0.38 as per table 9-3 or 0.35 as per Fig 9-2

Therefore w/c ratio = 0.35 (lower value governs)

Table 9-3 (Metric).

Relationship Between Water to Cementitious Material Ratio and Compressive

Strength of Concrete

|

Compressive Strength at 28 days, Mpa |

Water-cementitious materials ratio by mass |

|

|

Non-air-entrained concrete |

Air-entrained concrete |

|

|

45 |

0.38 |

0.30 |

|

40 |

0.42 |

0.34 |

|

35 |

0.47 |

0.39 |

|

30 |

0.54 |

0.45 |

|

25 |

0.61 |

0.52 |

|

20 |

0.69 |

0.60 |

|

15 |

0.79 |

0.70 |

Air Content: According to Table 9-5, a target air content of 1.5% is recommended for aggregate of size 25-mm.Therefore, we can design the mix for 1%- 3% air and use 3% for batch proportions. The trail batch air content must be within ±0.5 % of the maximum allowable air content.

Table 9-5 (Metric). Approximate Mixing Water and Target Air Content

Requirements for Different Slumps and Nominal Maximum Sizes of Aggregate

|

Slump, mm |

Water, Kilograms per cubic meter

of concrete, for indicated sizes of aggregate |

|||||||

|

9.5 mm |

12.5

mm |

19 mm |

25 mm |

37.5

mm |

50 mm |

75 mm |

150 mm |

|

|

|

Non-air-entrained concrete |

|||||||

|

25 to 50 |

207 |

199 |

190 |

179 |

166 |

154 |

130 |

113 |

|

75 to 100 |

228 |

216 |

205 |

193 |

181 |

169 |

145 |

124 |

|

150 to 175 |

243 |

228 |

216 |

202 |

190 |

178 |

160 |

- |

|

Appropriate amount of entrapped

air in non-air-entrained concrete, percent |

3.0 |

2.5 |

2.0 |

1.5 |

1.0 |

0.5 |

0.3 |

0.2 |

|

|

Air-entrained concrete |

|||||||

|

25 to 50 |

181 |

175 |

168 |

160 |

150 |

142 |

122 |

107 |

|

75 to 100 |

202 |

193 |

184 |

175 |

165 |

157 |

133 |

119 |

|

150 to 175 |

216 |

205 |

197 |

184 |

174 |

166 |

154 |

- |

|

Recommended average total air

content, percent, for level of exposure: |

|

|||||||

|

Mild exposure |

4.5 |

4.0 |

3.5 |

3.0 |

2.5 |

2.0 |

1.5 |

1.0 |

|

Moderate exposure |

6.0 |

5.5 |

5.0 |

4.5 |

4.5 |

4.0 |

3.5 |

3.0 |

|

Severe exposure |

7.5 |

7.0 |

6.0 |

6.0 |

5.5 |

5.0 |

4.5 |

4.0 |

Slump: The slump is specified at 25-mm to 75-mm. However, for proportioning purpose, we shall use 75mm ± 20mm.

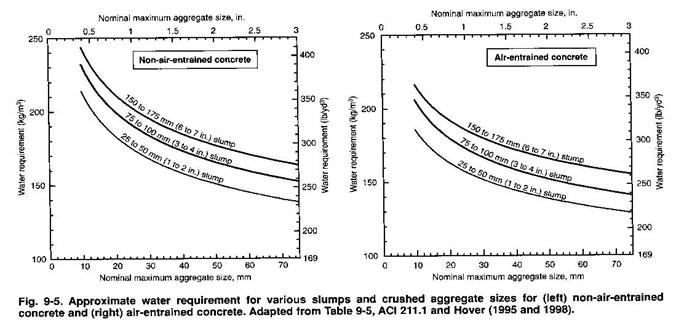

Water content: In accordance with Table 9-5 or Fig 9-5, the required water content for a 75-mm slump, Non-air-entrained concrete with 25-mm aggregate size is about 193 Kg/m3. However, the rounded gravel would need only 168 Kg/m3. (193 – 25). Also, the water reducers would also result in reduction of 10%. Thus the final water content would be:

168 – (10% of 168) = 151.2

Kg/m3.

Cement Content: On basis of w/c ratio of 0.35 and water content of 151.2 Kg/m3,

The cement content required will be:

151.2/0.35 = 432 Kg/m3.

This is greater than the 310 Kg/ m3 on basis of aggregate size and also greater than 335 Kg/m3 required for severe conditions (Table 9-7).

Table 9-7. Minimum

Requirements of Cementing Materials for Concrete Used in Flatwork

|

Nominal maximum size of aggregate, mm (in.) |

Cementing materials, Kg/m3 (lb/yd3)* |

|

37.5 (11/2) |

280 (470) |

|

25 (1) |

310 (520) |

|

19 (3/4) |

320 (540) |

|

12.5 (1/2) |

350 (590) |

|

9.5 (3/8) |

360 (610) |

*cementing materials

quantities may need to be greater for severe exposure. For

example, for deicer exposures, concrete should contain at least 335 Kg/m3

(564 lb/yd3) of cementing materials.

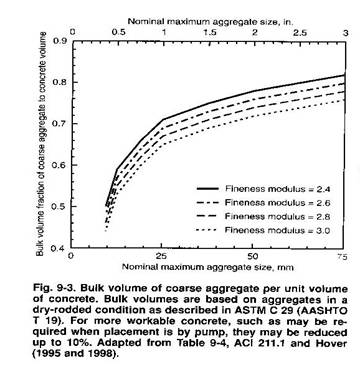

Coarse aggregate content: The bulk volume of CA (of 25-mm size) recommended when using sand with fineness 2.80 is 0.67. (Table 9-4 or Fig 9-3).

Therefore the ovendry mass of CA for a cubic meter of concrete will be density times the volume.

i.e. 1700 * 0.67 = 1139

Kg.

Table 9-4. Bulk

Volume of Coarse Aggregate Per Unit Volume of Concrete

|

Nominal maximum size of aggregate,

mm (in.) |

Bulk volume of dry-rodded coarse

aggregate per unit volume of concrete for different fineness moduli of fine

aggregate |

|||

|

2.40 |

2.60 |

2.80 |

3.00 |

|

|

9.5 (3/8) |

0.5 |

0.48 |

0.46 |

0.44 |

|

12.5 (1/2) |

0.59 |

0.57 |

0.55 |

0.53 |

|

19 (3/4) |

0.66 |

0.64 |

0.62 |

0.6 |

|

25 (1) |

0.71 |

0.69 |

0.67 |

0.65 |

|

37.5 (11/2) |

0.75 |

0.73 |

0.71 |

0.69 |

|

50 (2) |

0.78 |

0.76 |

0.74 |

0.72 |

|

75 (3) |

0.82 |

0.8 |

0.78 |

0.76 |

|

150 (6) |

0.87 |

0.85 |

0.83 |

0.81 |

Admixture Content:

The amount of water

reducer per cubic meter of concrete is:

4 * 432 = 1728 g or

1.728 Kg.

Fine Aggregate content:

At this point, we have calculated the amount required of all

the ingredients except fine aggregate.

By the Absolute volume method, FA content can be obtained by

subtracting the absolute volumes of the known ingredients from 1 cubic meter.

Absolute volume is calculated by dividing the mass of ingredient by the product of its relative density and the density of water:

Water = ![]() = 0.1512 m3.

= 0.1512 m3.

Cement =

![]() = 0.144 m3.

= 0.144 m3.

Air

= ![]() =

0.030 m3.

=

0.030 m3.

Coarse aggregate = ![]() = 0.422 m3.

= 0.422 m3.

---------------

Total Volume of known ingredients = 0.747 m3.

Hence, absolute volume of FA is: 1 – 0.747 = 0.253m3.

The mass of dry FA

is: 2.60*0.253*1000 = 657.8 Kg.

Thus, the proportions before trial mixing per cubic meter of concrete are:

Water 151.2 Kg

Cement 432.0 Kg

Coarse aggregate (dry) 1139.0 Kg

Fine aggregate (dry) 657.8 Kg

--------------

Total mass 2380.0 Kg

Water reducer 1.728 Kg

Slump 75 mm (±20 mm for trial batch)

Estimated concrete density (using SSD aggregate) =

151.2 + 432 + (1139*1.005) + (657.8*1.006)

= 2389.64 Kg/m3.

Note: (0.5% absorption / 100) + 1 = 1.005

(0.6% absorption / 100) + 1 = 1.006

Correction for moisture:

Test indicates that for this example, CA moisture content is 1.5 % and FA moisture content is 5 %.

Now the trial batch aggregate proportions become:

CA = 1139.0*1.015 = 1156.09 Kg.

FA = 657.8*1.05 = 690.69 Kg.

Note that water absorbed by the aggregate does not become part of mixing water and hence must be excluded from water adjustment.

Surface moisture contributed by CA = 1.5 % - 0.5 % = 1.0 %. = 0.010

FA= 5 % - 0.6 % = 4.4 %. = 0.044

Thus, the estimated requirement for added water becomes:

151.2 – (1139*0.010)-(657.8*0.044) = 110.87 Kg.

Now the revised proportions of batch taking moisture into consideration are:

Water (to be added) 110.87 Kg

Cement 432.00 Kg

Coarse aggregate (1.5% MC, wet) 1156.09 Kg

Fine aggregate (5% MC, wet) 690.69 Kg

--------------

Total mass 2389.65 Kg

Water reducer 1.728 Kg