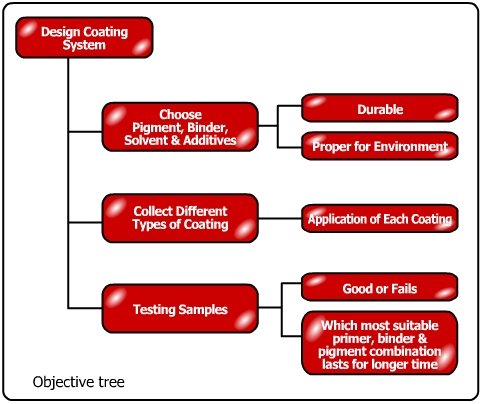

The factors affecting the design are shown in the objective tree. One critical factor in designing is the environment to which the coating would be subjected.

Information on climatic data is important in designing a coating system.

The following parameters are included in the climatic data.

-

Dry bulb temperature

-

Humidity

-

Wind speed

-

Average rainfall

-

Pollution

Summary of climatic data of Dhahran

-

Average dry bulb temperature, maximum. 44.290 C, minimum 22.800 C

-

Average relative humidity, maximum. 82.24%, minimum 18.4%

-

Average wind speed 4 m/sec

The above average is for the month of August which is one of the hottest and humid month, the average is base on ten years data)

A coating suitable for Dhahran typical of sea coastal environment was to be selected and evaluated.

Six samples of size 21 cms (L), 11 cms (W) were prepared. Two diagonal scratches were made on the samples.

The following samples were selected.

Sample # 1: A sample coated with solvent free amine cured epoxy.

Appearance: Light blue

Sample # 2: A two layer coating comprising of high build polyamine adduct cured coal tar epoxy coating ( both layer with same constituents).

2nd coat: 7472 SIGMA TCN 300 150 MIC

Appearance: Black

Sample #3: A three layer coating of polyamide cured epoxy primer.

2nd coat: 7682 SIGMA CAP COATING EP 125 MIC

3rd coat: 7690 SIGMA CAP FINISHES PU 75 MIC

Appearance: Milky White

Sample # 4: A three layer coating comprising of polyamide cured epoxy primer.

2nd coat: 7682 SIGMA CAP COATING EP 125 MIC

3rd coat: 7690 SIGMA CAP COATING EP 100 MIC

Appearance: White

Sample # 5: A three layer coating with high build amine adduct cured phenolic epoxy primer.

2nd coat: 7435 SIGMA PHENGUARD COATING EP 100 MIC

3rd coat: 7436 SIGMA PHENGUARD FINISH 100 MIC

Appearance: Grey

2nd coat: 0811 SIGMA COLOR UNDEROCAT 35 MIC

3rd coat: 0818 SIGMA COLOR GLOSS 35 MIC

Appearance: Pink

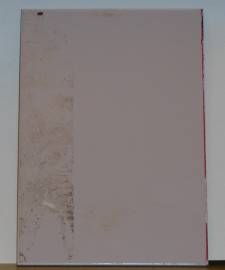

All samples were evaluated for their resistance to corrosion in a salt spray cabinet.

The arrangements of the samples are shown below.

Experimental parameters according to specification B 117-97 (ASTM)

Salt spray (fog) equipment containing a 3.5 wt% salt solution reservoir, compressed air, atomizing nozzle, specimen supports, provision for heating.

The specimen were placed on supports so as not to contact any metallic surface and allowing free settling of fog.

The pH of the solution was maintained in the range 6.5 -7.0, the temperature in the chamber was maintained at 35o C + 1.1-1.5o C. All specimens were exposed for one week.

Based on the visual inspection and the metallographic examination the extent of rust which developed was assessed.

As shown in the following figures, the best resistance was offered by Sample # 3 (three layered polyamide coating) followed by Sample # 2 ( high build polyamide adduct cured coal tar epoxy coating).