| Objective | To demonstrate intergranular corrosion of sensitized steels. | |

| Materials | 18-8 Steel specimens | |

| Furnace | ||

|

|

||

| Procedure |

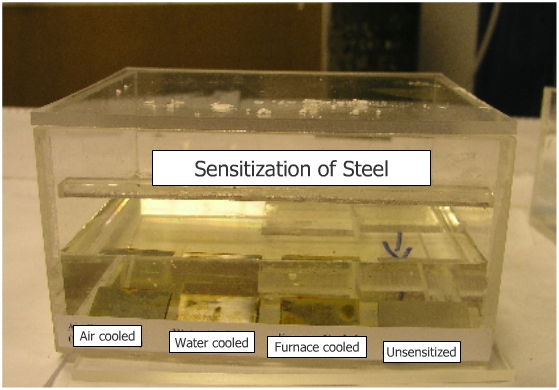

Heat the three coupons of stainless steel in the furnace to 648oC for one hour in the sensitizing zone. For most stainless steels the sensitizing temperature range is between 400 -850oC. Take out one sample, air cool the sensitized specimen an then place it in a salt water together with an untreated (unsensitized sample).

After a day, remove the specimen and

drop them on the floor. Compare the sounds they produce. Of the other two samples, quench one specimen and furnace cool the other.

Immerse both the specimens in the 3.5% NaCl solution (corrosive

media). Remove them after one day. Drop the samples on the floor and

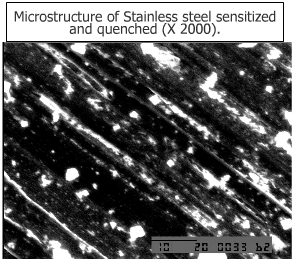

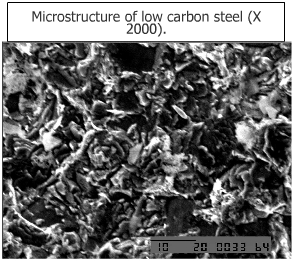

note the difference in the sound. Sensitized stainless steel when dropped on the floor has no longer a metallic sound like most metals. Instead it sounds like a piece of lead. This is generally caused by separation of grain called intergranular corrosion caused by the depletion of chromium at the grain boundaries due to the formation of chromium carbide. To resist corrosion steel must contain at least 12% chromium. The grain boundary attack is shown in the following figures.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|