| 8. Prevention by Design | |

|

8.7 Design for Liquid Containers |

|

Liquid Containers

A good design for liquid container must offer the following:

a) Freedom from sharp corners and edges.

b) Smooth flow of liquid from the container.

c) Freedom from the buildup of water traps around the corners.

d) Complete drainage from the corners without any water traps. The elimination of water traps is essential to minimize the formation of differential oxygen cells which lead to corrosion.

e) Minimizing of bimetallic corrosion by joining compatible materials without the risk of galvanic corrosion.

f) Complete internal and external coating of the containers, if cost effective.

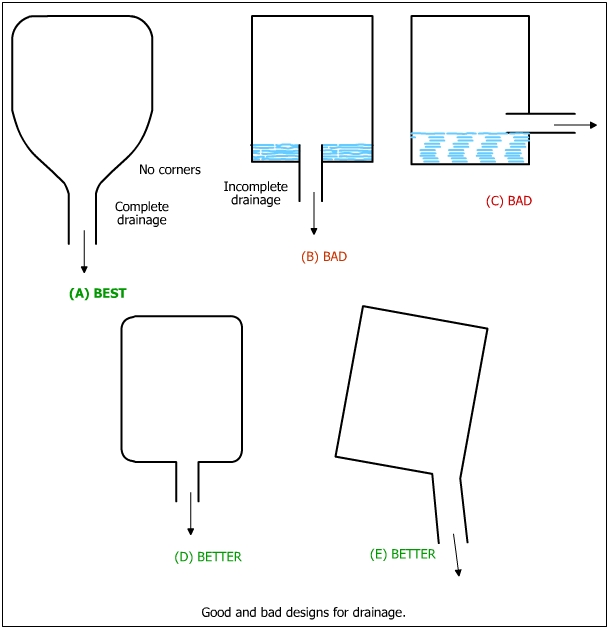

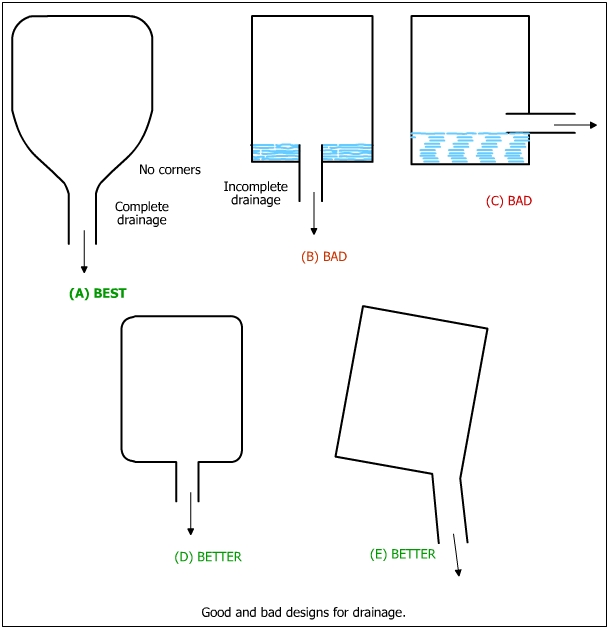

Some of the above measures to prevent corrosion in liquid containers are shown in the following figure. Figure (A) shows the best design because of the capability of the liquid containers for complete drainage and absence of water traps. Figure (B) and (C) are examples of bad design because of the incapability for complete drainage and presence of water and moisture traps around the corners. Better designs are shown in Figures (D) and (E).

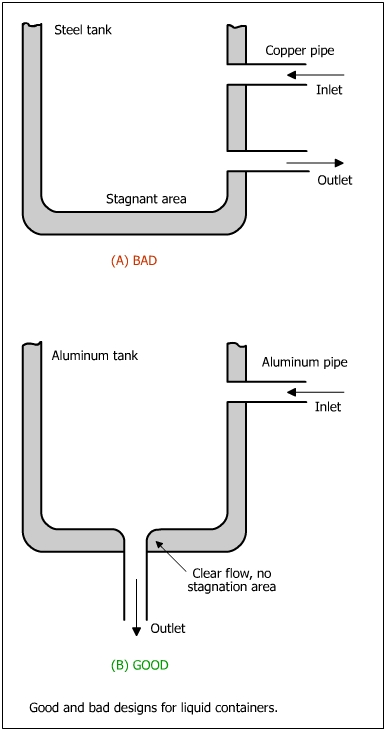

Figure (A) shown below is an example of a bad design because of the joining of a copper pipe with the galvanized steel tank. The copper ions may be plated on the surface of galvanized steel and lead to pitting. An aluminum inlet pipe joined to an aluminum tank would not cause galvanic corrosion (Figure (B)). The design also offers a good drainage of the liquid. The design could be further improved by further smoothing the corners.

|

|