| Breakdown of protective system |

Many protective surface treatments, such as coating and welding, may not be very effective because of the presence of surface irregularities, voids, surface porosity, undercuts, and general surface roughness. The surface heterogeneities act as moisture traps and cause the damage.

|

| Poor fabrication |

Factors, such as improper welding, excessive cold working, and excess machining lead to failure.

|

| Lack of accessibility |

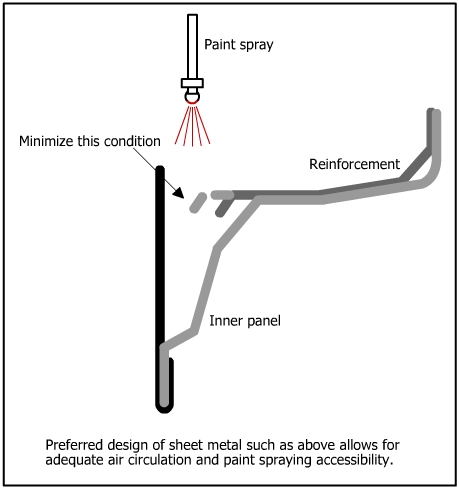

In complex systems, machinery, and components, there might be inaccessible areas due to lack of design insight where it may not be possible to carry out the corrosion protection measures. Interior of car doors are examples which are subjected to intensive localized corrosion. Figure shows a design which provides adequate air circulation and spraying accessibility.

|

| Structural heterogeneity in materials |

Joining similar materials with structural differences, such as differences in thermo-mechanical processing, grain size, number of impurity elements, grain boundary segregates, may cause deviation from the performance expected.

|

| Operating conditions |

Factors, such as temperature, pressure, and velocity, influence the service life if allowed to exceed the prescribed limits.

|