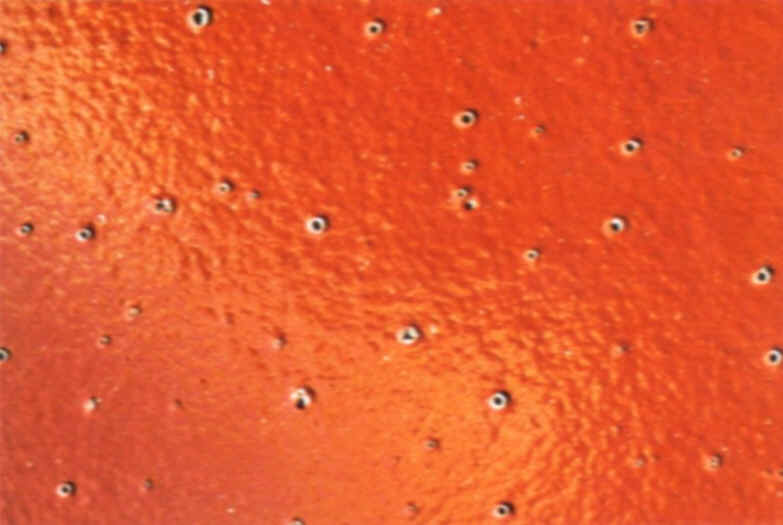

(C) Cratering

Identification:

Small, uniform indentations are formed in the film The indentations are like pits.

Description:

The defect is generally caused by mixing of contamination and dirt with the wet film. Some binders have inherent cratering tendency. On encountering contamination, they form craters. Cratering occurs before the complete drying up of the film. Cratering areas are potential sites for coating failures.

Remedy:

-

Remove the wet coating and re-paint. After the coating has cured, the coating surface in the crater area must be removed by sand blasting and applying another coat on the cratered area.