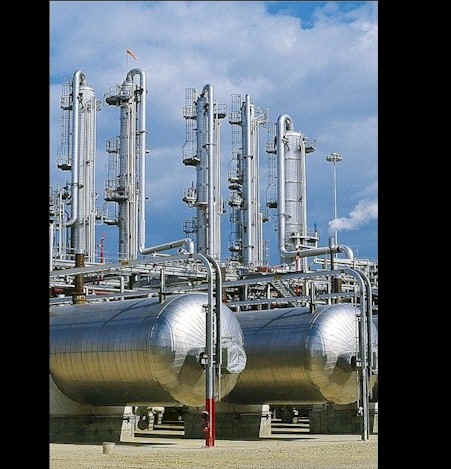

| Large scale construction |

Large scale steel construction such as railroad bridges, gas leaks, storage tanks, steel works and chemical plants need to be protected against corrosion by coating. about 90% are coated with paints based on organic binders.

|

| Automotive industry |

Automobile industry is one of the largest consumers of paints. The body shell of automobiles are made of steel, galvanized steel, aluminum alloys etc are subjected to pre-treatment by phosphate to obtain a homogeneous surface for application of the primer and the body coats. The type of coating applied differs from one manufacturer to the other. Cathodically protective coatings containing zinc have proved to be successful in warm and humid environments.

|

| Engines and Passenger Cars |

The exterior of passenger cars and vehicles are painted in a three coat system. Anti-corrosive primers are applied and followed by 40-50 mm two-pack polyethylene resin intermediate coat about 50 mm thick. Millionsof trucks, trailers and buses need coatings to achieve a maximum service life of at least ten years.

|

| Ships and Marine Transport |

Zinc silicate, epoxy cured with polyamide,epoxy cured with isocyanates, and polyurethane are widely used for marine tank coatings where the corrosion of steel and cargo is to be prevented. Chemical tanks have a very severe environment because they may have to transport crude oil, refined gasoline, solvents,diesel oil as well as alkalies and acids.

|

| Domestic Appliances |

All domestic appliances such as refrigerators, dishwashers, washing machines need to be coated. Paint systems that cure in a short time at high temperature (10 min at 160oC) are used. Acrylics are used as binders which give a smooth film by polycondensation. 2000 pack polyurethane coatings are also applied.

|

| Food cans |

Coatings based on polyester acrylic resins with melamine resin are used for can exterior. Epoxy phenolic resins are used for interior coating.

|

| Buildings |

Alkyd paints with mineral spirits are generally applied to protect the materials used in buildings. Water-borne systems with acrylates are also widely used.

|

| Oil Industry |

All oil transport pipelines must be coated. Fusion bonded epoxy coatings have been found to be very useful in the gulf region.

|

| Domestic Waste-water Treatment Plants |

Many factors which induce serious corrosion such as moisture, dissolved salts, hydrogen sulfide, ammonia, bacteria, etc. are present in waste water plants which imposes severe corrosion problems. A standard epoxy or coal tar coating system has been successfully used in these plants.

|

| Tank Bottoms |

Tank bottoms with various degrees of corrosion and pitting require a high film thickness. Solvent based coatings or epoxy, coal tar are not suitable for tank bottom. Solvent free coatings provide a good solvent.

|

| Atmospheric Exposure |

For aggressive environment, epoxy polyurethane systems have been successfully used.

|