Types of

Coating Systems

A coating system may use

different types of pigments depending on their attributes such as their

impermeability, their inhibition capabilities and cathodic protection.

| 1.

Impermeable systems |

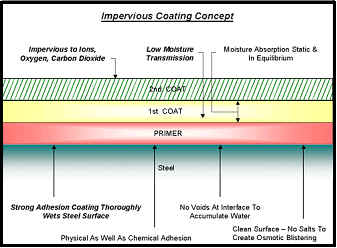

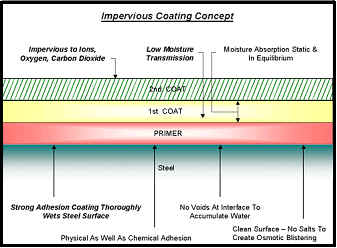

In these systems, the coating

must be impervious to air, oxygen, carbon dioxide as to the penetration of

ionic species. It must have good dielectric properties. A common example

is the application of coal tar enamel. The primer must be impermeable.

|

| 2.

Inhibitive systems

|

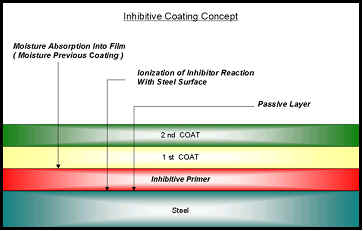

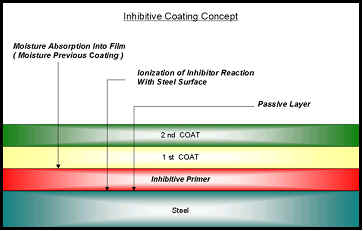

The success of this system

depends on the nature of inhibitive films which absorbs the penetrating

moisture and forms a passive film on the surface, thus blocking any

atmospheric intervention with the substrate to cause corrosion. Red lead

and lead chromates are good examples. These coatings are suitable for

application in the marine, industrial or atmospheric condition.

|

| 3.

Cathodically protective systems |

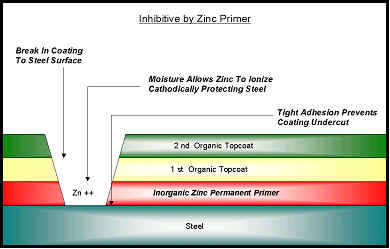

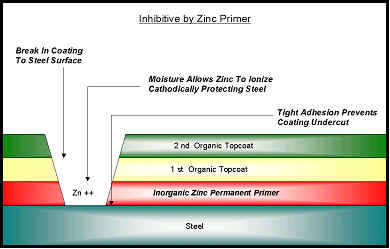

The

success of this system depends on the Zinc primer which are highly adherent to

the surface. The zinc protects the substrate by breakdown, releasing electrons

to the substrate and protecting it. Intermediate and top coats of

polyurethane, or vinyl have been successfully used for protection of

underground pipes.

|

Components

of Coating Systems

The chief components of coating

systems and their functions are:

| 1.Primers |

They provide a strong bond to the substrate

for adhesion. It includes rust inhibitors and wetting agents. They also

provide a compatible base for the top coats. They also prevent

corrosion. |

| 2.

Bodycoats

|

The bodycoats is applied to increase the

total thickness of coating. It provides strong adhesion, strong chemical

resistance and strong bond to primer and top coat. |

| 3. Topcoats |

They provide a sealing for the coating

systems and prevent the ingress of chemicals, water and other corroding

species. They also provide a pleasing color. |

Paints and

Coating Systems Categories

Basically

there are two categories:

-

Convertible

-

Non-convertible

Convertible

paints and coatings: They require a chemical reaction or polymerization

to form the protective coating film. Example: oil based points, alkyd paints,

epoxy coatings, etc.

Non

convertible paints and coatings: A two component paint of polyvinyl

chloride, zinc chromate and phosphoric acid. These coatings are applied to

enhance the adhesion of top coatings.