| 4. Forms of Corrosion | |

|

4.5 Intergranular Corrosion [3/3] |

|

Intergranular Corrosion of Stabilized Grades of Steel

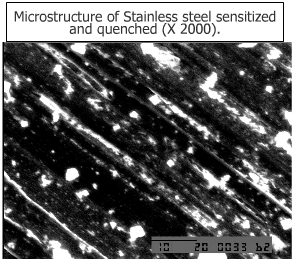

Surprising as it may seem, the stabilized grades of steel (steels containing Cb or Ti) may also exhibit intergranular attack under certain unfavorable conditions. The attack has been termed as "knife line attack" because of the knife like appearance in a very narrow band in the metal adjacent to the weld, whereas the weld decay described in the previous section occurs at a greater distance from the weld.

Mechanism

The temperature at the weld is of the order of 1650 oC. Because of the contact with the weld, the metal is also at a high temperature. Between the weld and the zone just next to the metal, a thermal gradient exists because of the poor thermal conductivity of the steel. If the temperature at the weld is around 1650 oC, the temperature of the metal adjacent to the weld in the unmelted region would be around 1425 oC. This region would contain all carbide in solution and no carbides would precipitate. If, however, for some reason, the metal is subjected to heating in the sensitizing temperature zone 510 - 780 oC, it would fail because chromium carbide would be precipitated and not columbium carbide, because of columbium carbide require a higher temperature. The steel would, therefore, behave as if it contained no stabilizer added (columbium or titanium) and is subjected to intergranular corrosion of the form of knife-line attack.

Stainless steel AISI 321 above the weld and stainless steel AISI 316 underneath the weld.

Above, right and along the weld knife-line attack is seen, whereas below, at some distance from the weld, weld decay and uniform attack is observed.

Remedy

Avoid any heat treatment which causes temperature to be reached in the sensitizing range because chromium carbides would immediately precipitated. heat the completed structure to about 1050 oC after welding to avoid knife-line attack.

|

|