|

lb.in. |

Where:

P is power in HP

n is speed in rpm

Machine Design - II (ME 308 Lab)

Shaft Design - Project # 1

Term 992

Steps # 1 & 2

|

lb.in. |

Where:

P is power in HP

n is speed in rpm

|

Where: T is torque in lb.in. from above r is the radius of the pulley in inches |

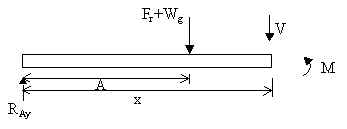

| Tangential force on the gear Ft = T1-T2 lb. Radial force on the gear Fr = Ft Tan f lb. |

Where: f is the pressure angle = 20° |

Resultant reaction is given by

![]() lb.

lb.

………………. Eqn. (11-9)

Where:

FR is the Catalog Load Rating

FD is the Design Load*

LD is the Design Life in Hours = 25000 Hrs.

nD is the Design Speed (given in rpm)

LRnR is the Rated Life = 106 rev.

R is the Reliability = 95%

a for Ball Bearings = 3

* for the values of FD, use the values of the resultant reactions calculated for locations B & D in step 5 of the lab-sheet, i.e. RB & RD

C=A.F. ´ FR

Where:

A.F. is the Load-Application Factor - use table (11-6)

NOTE:

![]()